- Lightweight, yet strong - optimally designed from a combination of steel and aluminum

- Labor savings, up to 12'-0" leg spacing reduces working point and re-shore requirements.

- Modular and flexible, length and width can be configured to any jobsite requirement

- Versatile, formwork for drop beams and column filler areas are integrated into the truss table

- Fast cycling, can be designed for up to 100'-0" long and 21'-0" wide with only 2 trusses.

- Truss table maximizes safety, speed and cost efficiency

- Easily adaptable to any building layout and room height using standard Doka parts

- Optimally designed from a combination of steel and aluminum providing a lightweight but high capacity solution

- Maximum leg spacing on the truss reduces adjustment points & greatly minimizes overall re-shore requirements

System

Versatility

The versatile design allows for maximum ganging of slab formwork. Between columns and certain slab perimeter conditions, the DokaTruss table can accommodate add on sections to form these areas and conveniently hinge back behind the table outline for trouble free resetting to the next floor.

![ganging of slab formwork]()

![DokaTruss Table]()

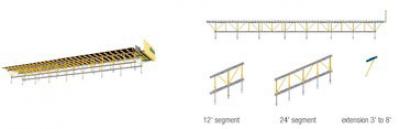

Flexible Sizes

The DokaTruss table can be designed for up to 100 feet in length and 21 feet in width with only two trusses. Any larger size can be done by adding in additional truss sections. Room heights from 8 feet up to 13 feet are done with the standard single legs. For higher rooms, the complete system is set on top of Doka’s Staxo 100 shoring that is one-hundred percent compatible with the DokaTruss table.

Speed

A fast speed height adjustment is built into the truss and the jack at the bottom allows for fine adjustment or steps up to 4 feet. When stripping, simple pin connections are released on the height adjustment legs and the truss is lowered with transportable jacks onto slab edge rollers and truss trolleys. This will always provide enough room to pick the table securely on four designed picking points before the table starts moving outside the structure.

![DokaTruss Table]()

![DokaTruss Table]()

DokaTruss table Solutions

(A) Between columns and any slab perimeter conditions, the DokaTruss table can accommodate add on sections to form these areas and conveniently hinge down and move as part of the Truss.

(B) Manual or remote controlled chain and compensators can be used to ensure fast and safe re-setting of the DokaTruss table.

(C) The joists can be doka standard h20 top timber beams – this design was done to have minimum deflection under heavy loads that results in a high quality concrete finish.

(D) For Decking, the plywood that fits the job the best can be used. This allows the contractor to be fully in charge of costs and concrete finish quality.

(E) The Truss is optimally designed from a combination of steel and aluminum, which keeps the weight of the complete table below 9.5 pounds per square foot.

(F) The perimeter walkway ensures a safe working environment.

Utilization

Flexible length combinations

DokaTruss tables can be designed in any combination of lengths to accommodate any building width and provide high flexibility.

![Flexible length combinations]()

![Adjustable Drop panel solution]()

Adjustable Drop panel solution

Drop beams, slab perimeter and between column forming can be built into the truss design to allow complete slab areas to be ganged and fly as a unit.

Lifting & Moving Devices for high speed repositioning

![Lifting & Moving Devices]()

![Slab edge rollers and truss trolley]()

Lowering the table on rollers

Slab edge rollers and truss trolleys allow for easy horizontal movement of the DokaTruss table when setting and stripping.

Move the table out of the building using crane rigging

Before the table starts moving outside the structure, the table is securely picked off four designed picking points.

![crane rigging]()

![flying the DokaTruss table]()

Lifting process and re-positioning

Methods of flying the DokaTruss table are based on the choice of the user. Pinching to the underside of the recently cast slab or using chain compensators are a couple of options available to ensure fast and safe re-setting of the DokaTruss table.

Often searched:

Documents & Downloads

- {{ item.category }}{{ item.title }}{{ item.lang | uppercase }}{{ label('label_available_for') }} {{ country | uppercase }}

No results found.